LEADING ICE CREAM GELATO MANUFACTURER AND WHOLESALE SUPPLIER IN SINGAPORE SINCE 2003

ENG

Ice Cream, Gelato and Sorbet Mini Cups and Pints (Customisable)

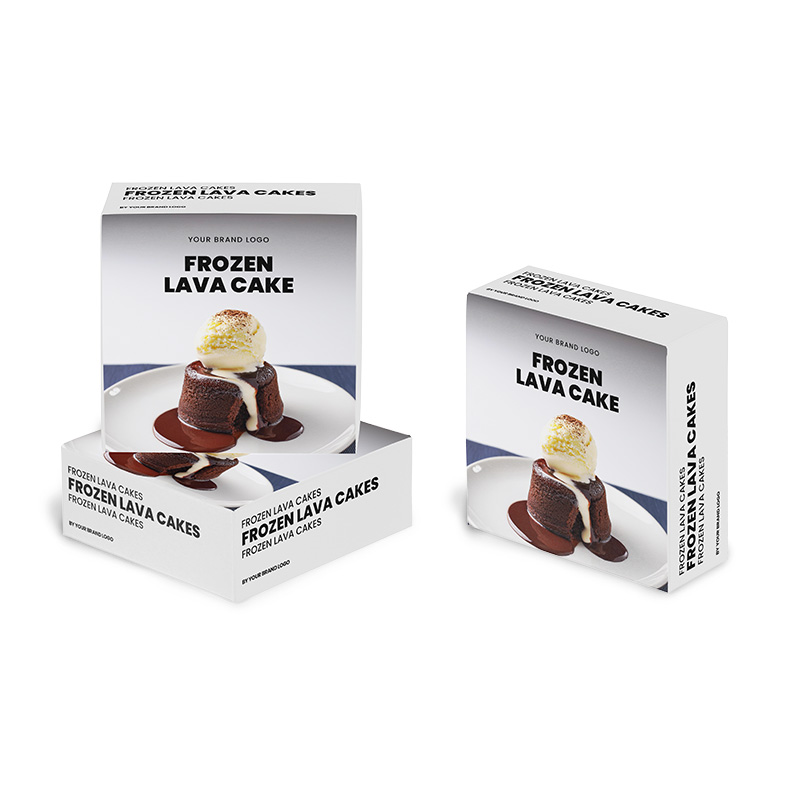

Frozen Lava Cakes

Oishi is dedicated to elevating your ideas into reality, with bespoke products tailored to your exact specifications.

Leveraging on our extensive experiences in ice cream, gelato, lava cakes and waffles manufacturing, Oishi provides a streamlined process from conceptualisation to execution, ensuring your brand makes a distinctive impact in the market.

Oishi Manufacturing has strategically invested in automation to optimize production efficiency and minimize costs. In 2023, the company introduced its BRC-accredited premix mixing and filling line. By early 2024, Oishi advanced to an FSSC 22000-certified continuous freezer line, moving away from traditional batch ice cream production. This state-of-the-art facility features a mini cup and pint packaging system, as well as ripple and ingredient feeders, enabling a wide variety of ice cream options for the retail market.

In 2022, Oishi further enhanced its offerings with the addition of an FSSC 22000-certified waffle production line, capable of producing various waffle types. Today, Oishi partners with leading QSR groups, catering companies, and retail brands through OEM contracts across its ice cream, premix, and waffle production capabilities.

Oishi provides customized solutions tailored to each client’s specific needs and requirements. We manage every aspect of the OEM process with precision, from raw material procurement and storage to certifications, packaging, product R&D, production, and delivery.

Oishi’s robust product research and development capability with core competence in:

Oishi’s strategic and professional approach ensures consistency, cost efficiency and safety, including:

Oishi practices effective warehouse storage, adhering to regulatory compliance ensuring:

In compliance to industry standards, certifications meeting regulatory requirements for market entry both locally and internationally, certifications applications on behalf of clients includes:

Oishi tailored solutions to meet unique needs focusing on key areas including:

Oishi possesses advanced manufacturing techniques, scalable production capabilities, and reliable delivery for boutique and large-scale global brands, with production

timeframe carefully met with remarkable quality control and delivery. Oishi has a regional network of distributions across:

FSO Compliant

ISO 22200 Certified

in product quality

Over 50 Flavours

Depth in range of quaility

Wide variety of products

To suit your requirements

Constant innovation

Customisation with own branding

Tailored one-stop solution

Always availble